Application

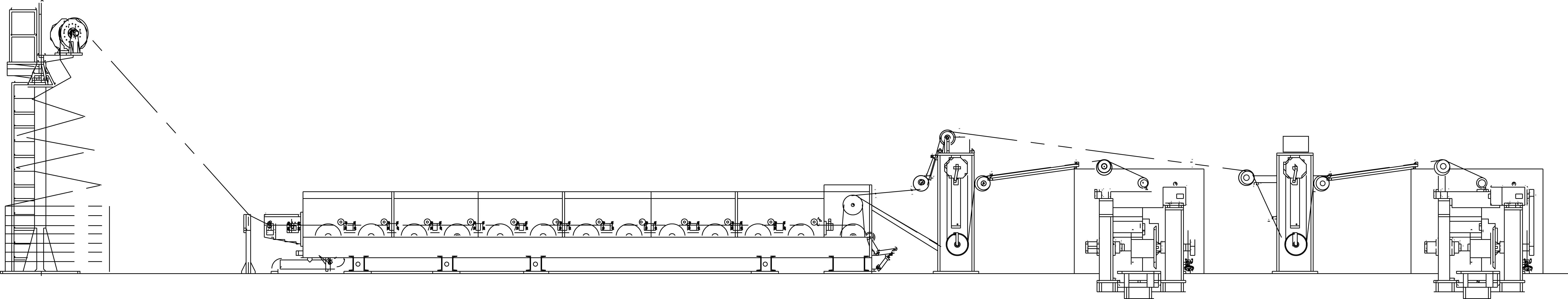

The non-sliding aluminum rod break down machine is designed for drawing the Φ9.5mm aluminum rod or al-alloy rod to round aluminum single wire with different sizes or same section, and then the wire will be coiled by the dual spooler or single-spooler.

Features

1. This aluminum wire drawing bench is well structured and comes with beautiful appearance.

2. Being independently driven by the AC variable frequency motor, the wire drawing drums can be synchronically adjusted in speed. Therefore, the wire drawing die can be quickly replaced.

3. The synchronous belt transmission is applied to the non-sliding aluminum rod break down machine, allowing for convenient maintenance.

4. Working status of all the equipment parts is controlled via the programmable controller and touch screen. With the screen, you can set and modify the relevant parameters for processing.

Product Improvement

1. A real-time tension control system is designed. Via the operating screen, the tensile force can be directly set and displayed.

2. According to the aluminum rods of different strength, you can choose different size wheel pulley.

Advantages

1. The non-sliding aluminum rod break down machine is convenient in mold matching, as a result of the quick mold change system driven by a fractional motor.

2. Non-sliding wire drawing is beneficial for extending the service life of the wheel rim and wire drawing die.

3. This wire drawing machinery is more efficient and energy-saving. That is because it makes full use of the converter technique.

4. The machine is suitable for the special shape wire drawing.

Sales Case

Our non-sliding aluminum rod break down machine has been well accepted in the countries including turkey, Iran, etc.

| Drawing capstan dia. (mm) | Quantity of wire | Drawing times | Applicable wire dia. (mm) | Dia. of finished product (mm) | Max. drawing speed (m/s) |

| 450 | 1 | 9 | 9.5 | 2.8-5.0 | 22 |

| 450 | 1 | 11 | 9.5 | 2.2-5.0 | 25 |

| 450 | 1 | 13 | 9.5 | 1.8-5.0 | 25 |

| 450 | 2 | 13 | 9.5 | 2.0-5.0 | 25 |