Application

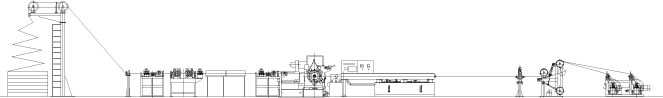

This extrusion machine is used for making flat copper, aluminum, or alloyed wires, copper or aluminum bars, special-shaped aluminum tube, aluminum-coated steel, or other products.

Product Features

1. Unique Technology

The raw materials is fed into a groove wheel, and then gets into the die cavity under the function of friction force. The groove wheel rubs and shears the extrusion materials to generate enough temperature and pressure, so that the metal can be extruded out from the die. The extruder works continuously to produce the product with required length.

2. Excellent Finished Product Quality

This extruding machine makes smooth copper or aluminum product free from cracks or sharp edges. The finished product comes with excellent mechanical property and stable geometric stability.

3. Low Production Cost

This easily operated copper/aluminum extrusion machine can be used to make products of different specifications. Its mold can be instantly replaced. Only 2 to 4 operators are required.

Advantages

The highly efficient extrusion machine is featured by simple structure, low investment, low energy consumption, convenient operation, and many more.

Sales Performance

This equipment sells well in the domestic market. It has been exported to India, Indonesia, and other areas.

| Aluminum Extruder | |||||||

| Type | Diameter of Groove Wheel(mm) | Max. Width of Finished Product(mm) | Section of Finished Product (mm) | Tube Diameter (mm) | Tube Thickness (mm) | Output Capacity (kg/h) | Rod Size (mm) |

| 300 | 300 | 40 | 10~240 | Ø5~Ø32 | 0.5~5 | 180 | Ø9.5,Ø12.5 |

| 350 | 350 | 80 | 15~800 | Ø6~Ø50 | 0.5~5 | 250~500 | Ø9.5,Ø12.5 |

| 400 | 400 | 180 | 15~2400 | Ø20~Ø80 | 1.4~5 | 250~800 | Ø12.5,Ø15.0 |

| 550 | 550 | 250 | 15~2800 | Ø50~Ø170 | 1.4~5 | 250~1000 | Ø12.5,Ø15.0 |

| Copper Extruder | ||||||

| Type | Diameter of Groove Wheel (mm) | Max. Rotary Speed of Groove Wheel (mm) | Max. Width of Finished Product (mm) | Section of Finished Product (mm) | Output Capacity (kg/h) | Rod Size (mm) |

| 300 | 300 | 12 | 45 | 10~240 | 400 | Ø12.5 |

| 350 | 350 | 12 | 85 | 20~850 | 400~800 | Ø16(Ø17) |

| 400 | 400 | 10 | 170 | 100~2400 | 400~1250 | Ø17,Ø20 |

| 550 | 550 | 7 | 220 | 100~2800 | 800~2000 | Ø20,Ø25 |

55055025015~2800Ø50~Ø1701.4~5250~1000Ø12.5,Ø15.0