Application

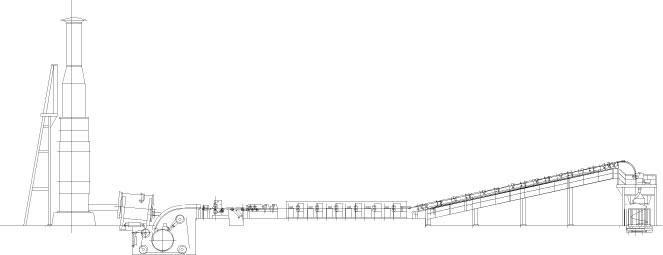

1. When equipped with the shaft furnace, the copper rod continuous casting and rolling line applies the electrolytic copper as the main raw materials. It is dedicated for making Φ8mm copper rod.

2. This copper rod continuous casting and rolling equipment, if installed with a reverberatory furnace, utilizes the copper scrap to produce Φ8mm copper rod. Sometimes, the copper rod is added with a moderate amount of electrolytic copper.

Technological Process

1. Electrolytic copper as the raw materials

Electrolytic copper → vertical furnace → heat preserving furnace → launder → pouring ladle → five wheel type continuous casting machine → front traction apparatus → slitting roller → ingot carrier → straightening and chamfering machine → feeding device → double-roller continuous mill → copper rod cooling system → back traction device →Rod Coiler

2. First grade copper scrap as the raw materials

First grade copper scrap → reverberatory furnace → launder →pouring ladle→ five wheel type continuous casting machine → front traction apparatus → slitting roller →ingot carrier →straightening and chamfering machine → feeding device → double-roller continuous mill → copper rod cooling system → back traction device →Rod Coiler

| Copper Bar Diameter | Φ8mm |

| Melting Furnace | Vertical copper melting furnace + rotary holding furnace |

| Height of Vertical Furnace | About 19m |

| Diameter of Crystallization Wheel | Φ1800mm |

| Sectional Area of Crystallization Tank | 2348mm2 |

| Rolling Form | Vertical and horizontal rolling |

| Number of Rolling | 12 |

| Roller Size | Φ270mm |

| Initial Rolling Speed | 0.23m/s |

| Max. Finished Rolling Speed | 9.6m/s |

| Production Capacity | 13~15t/h |

| Copper Coil Size (O.D.×I.D.×H) | Φ1.8×Φ0.9×1.0(m) |

| Copper Coil Weight | 1~4t |

| Centre Height of Rolling Mill | 1500mm |

| Total Installed Capacity | 1000KW |

| Overall Dimensions (L*W*H) (Exclude smelting furnace as well as cooling and filtering system) |

43.0×7.8×5.6(m) |

| Copper Melting Furnace | 1 set |

| Holding Furnace | 1 set |

| Five Wheel Type Continuous Casting Machine | 1 set |

| Traction Apparatus | 1 set |

| Automatic Shear | 1 set |

| Ingot Carrier | 1 set |

| Straightening and Chamfering Machine | 1 set |

| Double-roller Continuous Mill (Including feeding device) | 1 set |

| Copper Rod Cooling System | 1 set |

| Rod Coiler | 1 set |

| PLC Control System | 1 set |

Purpose: The equipment is used for producing copper rod through the melting, casting, and the continuous rolling process from the electrolytic copper and/or copper scrap.

Parameters| Casting Equipment | Rolling Machine | ||||

| Casting wheel dia. (mm) | Type of roll stand | Quantity of roll stand | Roller dia. (mm) | Finished rod dia. (mm) | Max. production capacity (t/h) |

| Φ1800 | 2-roller | 12 | Φ270 | Φ8 | 8.5 |